Do you need new press tools or to modify your existing ones? Feel free to email or call us. We would be happy to help you.

Design and production of stamping tools - Toolshop

The manufacturing process consists of two stages: the development and the manufacture of tools, applying the method of sheet-metal cold-forming. These are mainly tools for the manufacture of structural components and heat shields for the automotive industry. The first step is to design the pressing process for sheet-metal products. It is designed using the simulation software PanStamp 2G which enables specialists to transform their ideas into actual models.

Development and manufacturing process of press tools

The next step is the design engineering in CATIA V5 software. PowerSHAPE, Mechanical Desktop (3D) and AutoCAD (2D) software, among others, are used to modify the models during programming of the machining. Subsequently, the client's specification is incorporated, and the manufacturing process begins. When complete, the tools are delivered fully checked, adjusted, and tested. Pre-series delivery of pressed parts or modification of existing press tools is also possible upon request. The high-level technological knowledge of our production team ensures the highest quality of tools always delivered to schedule.

Technologies & Services

- 5-axis and 3-axis CNC machining

- Electro-erosive cutting

- Conventional machining, i.e. milling, turning, drilling, grinding

- 3D measuring and optical scanning

- Testing and adjustments of tools

Our products

- Transfer tools

- Compound & follow-on tools

- Tandem tools

- Pulling tools

- Shearing tools

References

Gallery

Machinery

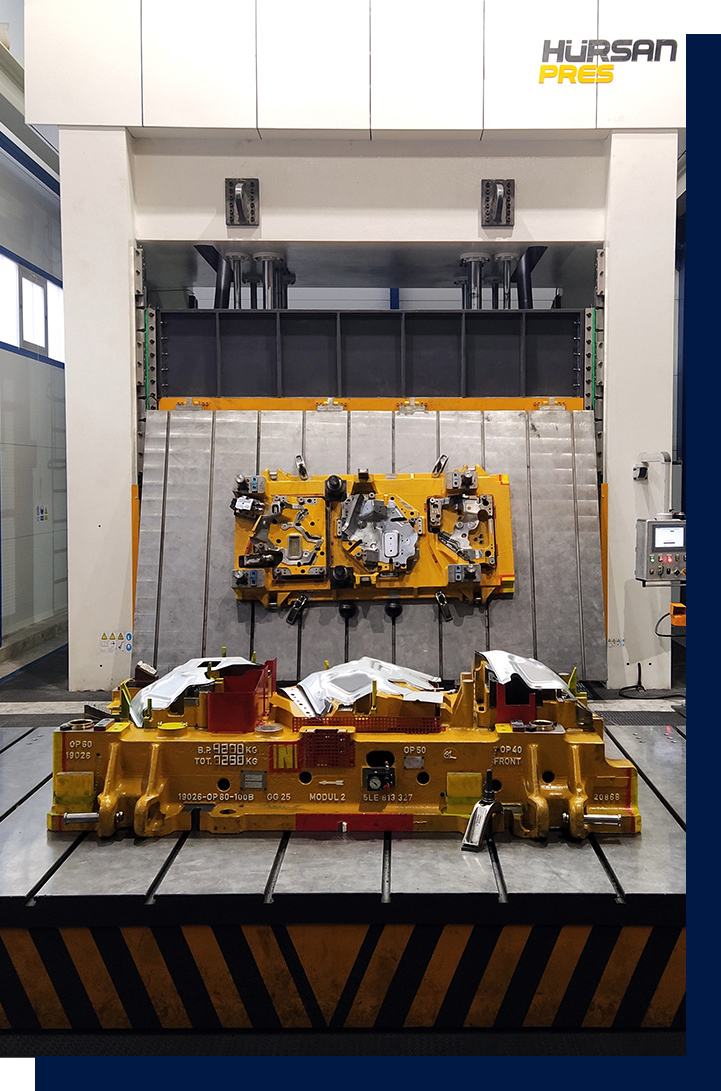

Try-out press Hürsan

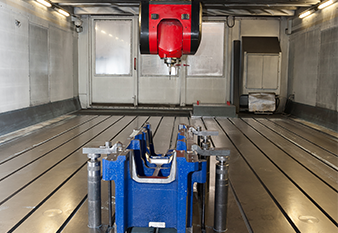

CNC portal milling machine TRIMILL VM 6535

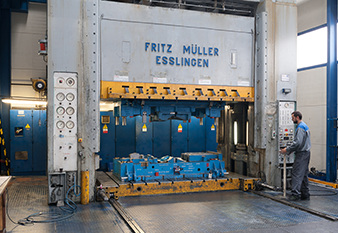

Testing press Müller 1200

CNC milling machines

Get in touch